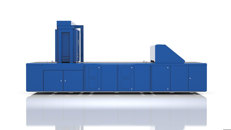

Ideal printer for sectors:

-

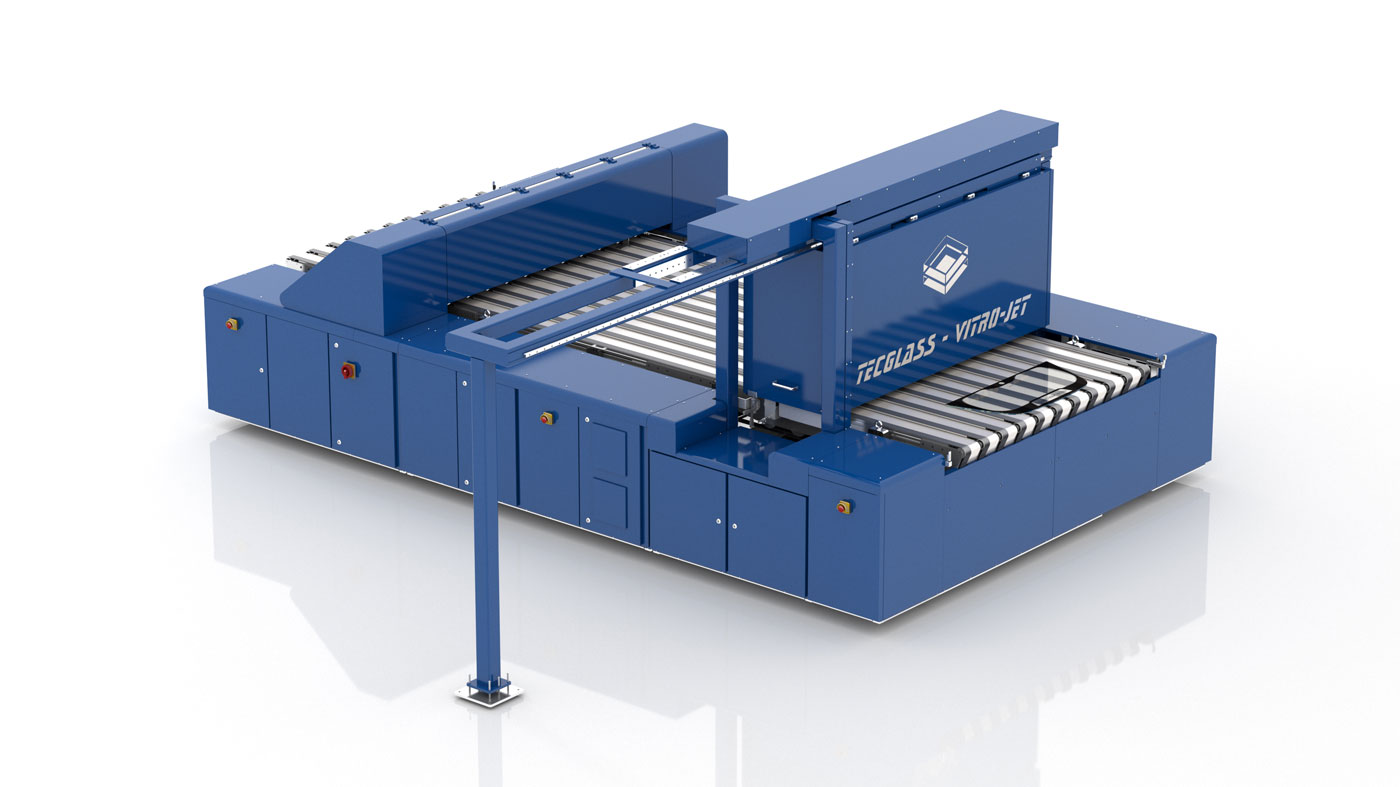

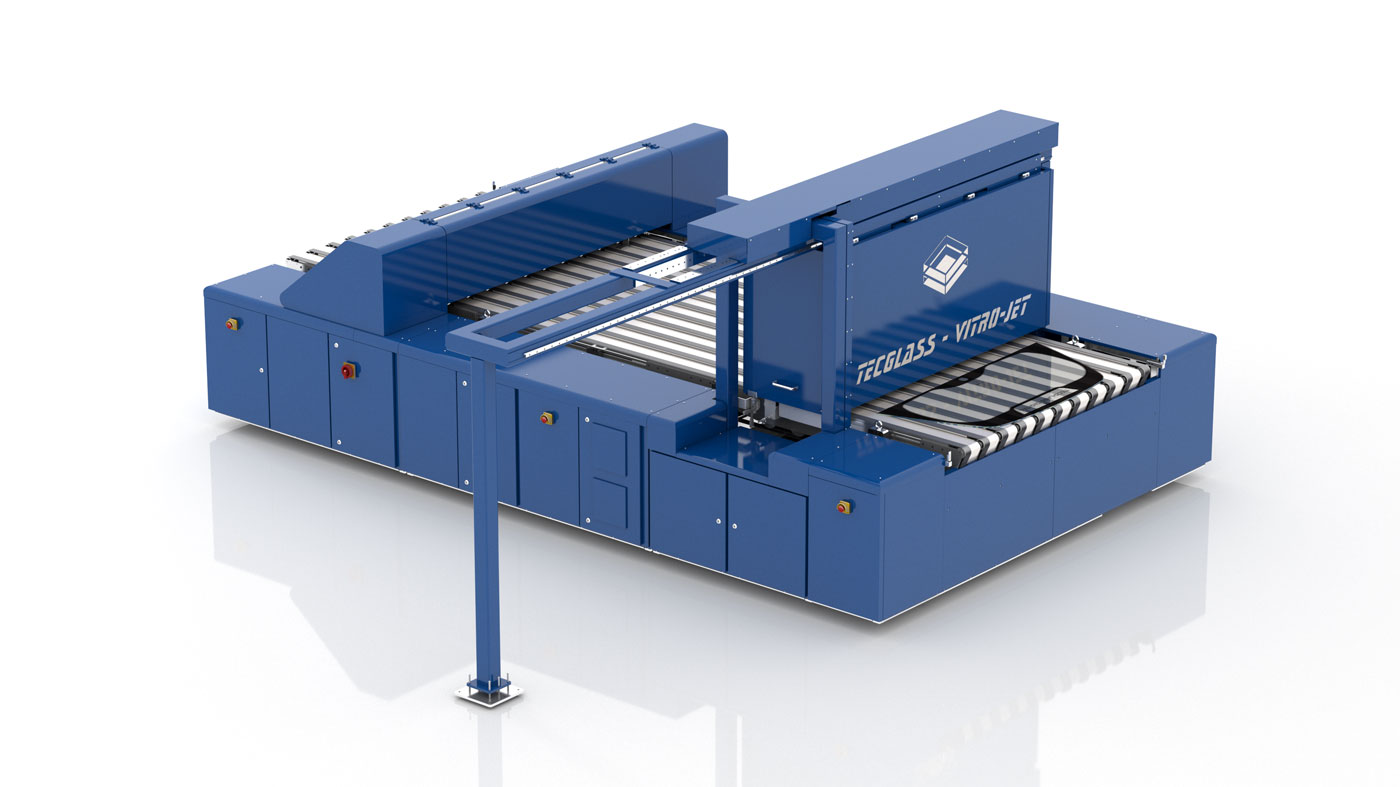

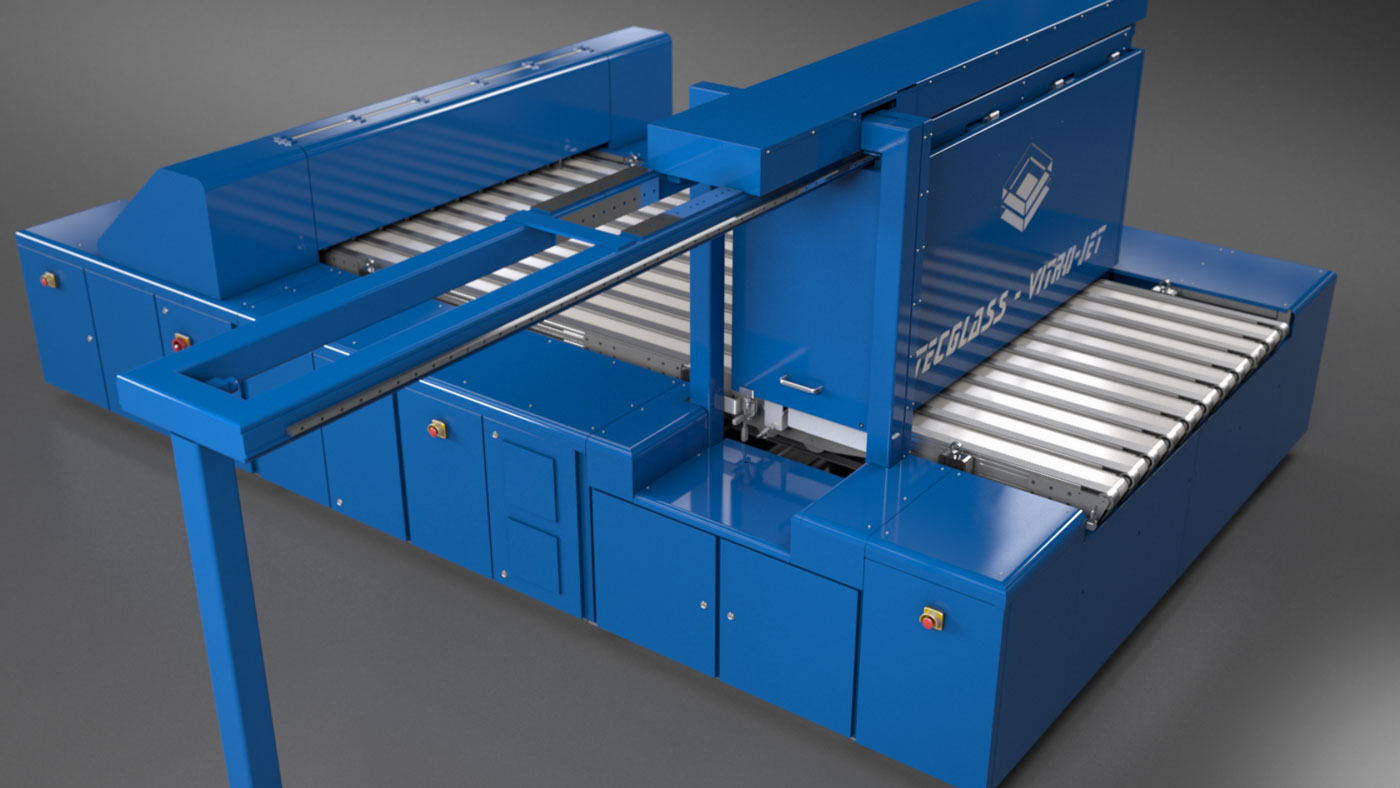

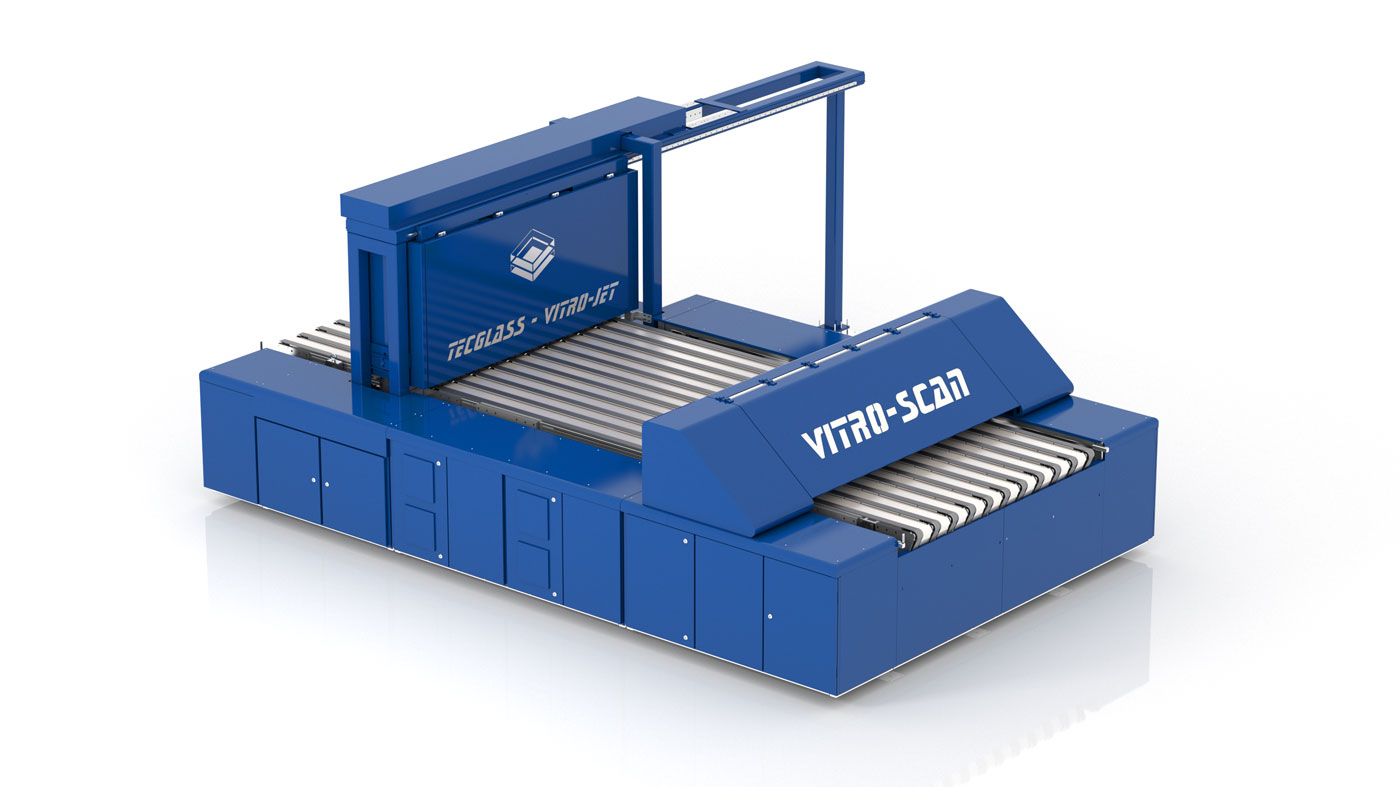

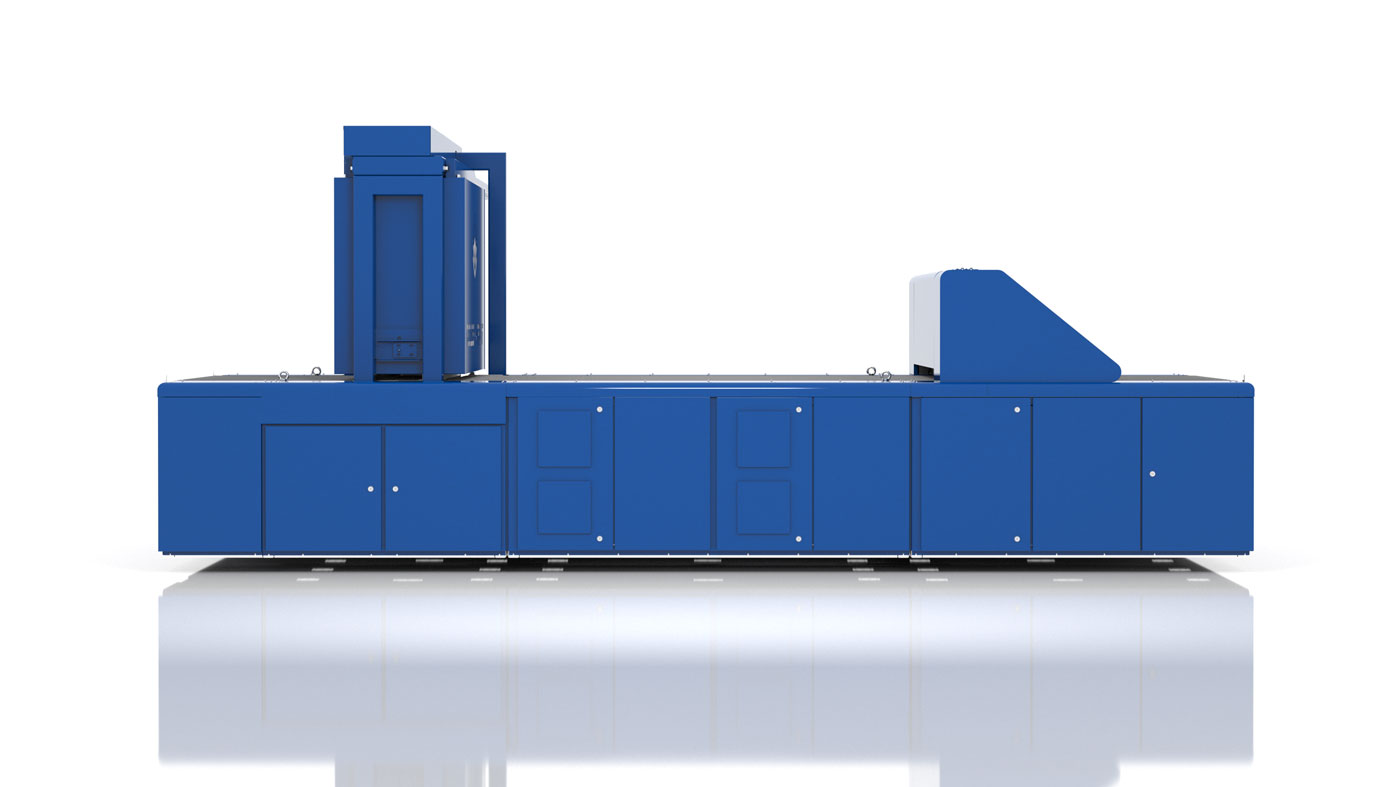

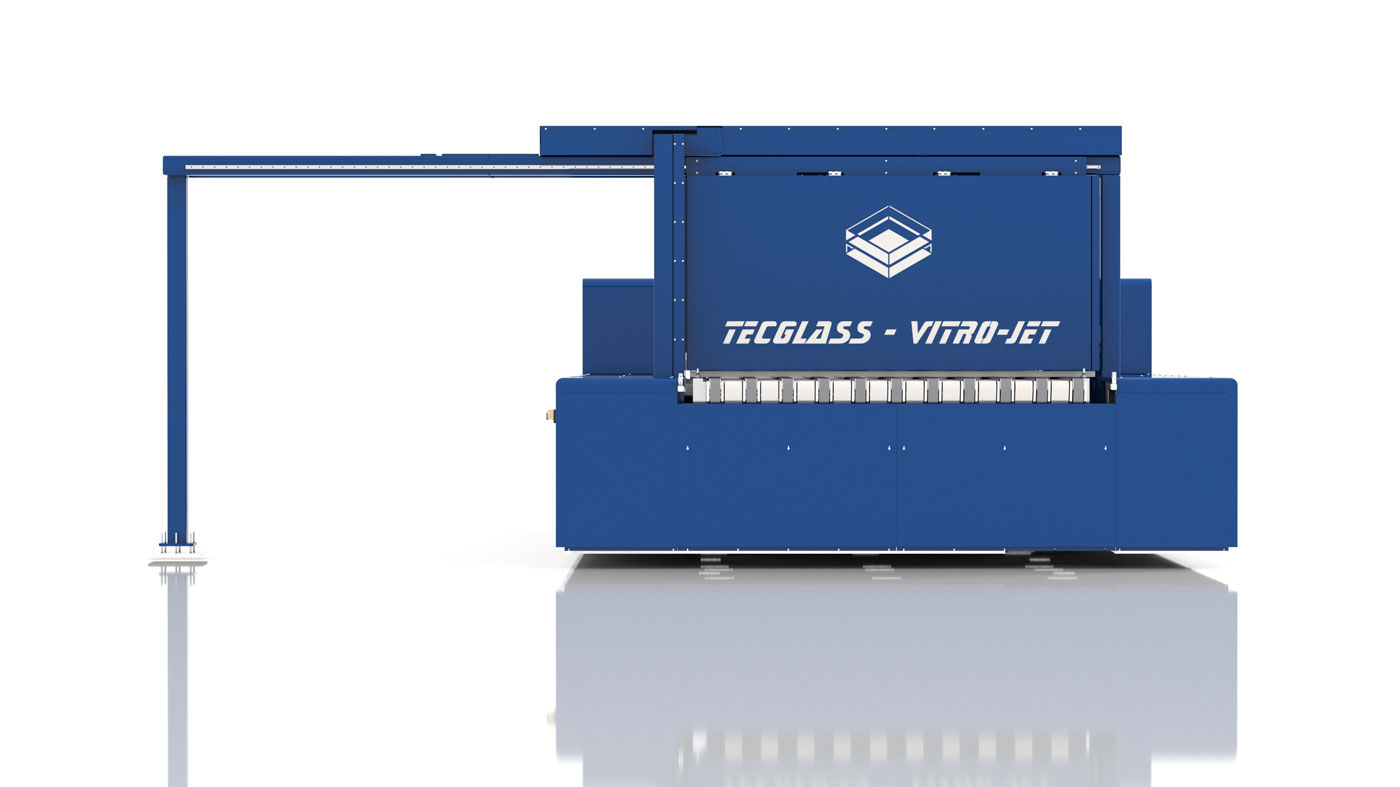

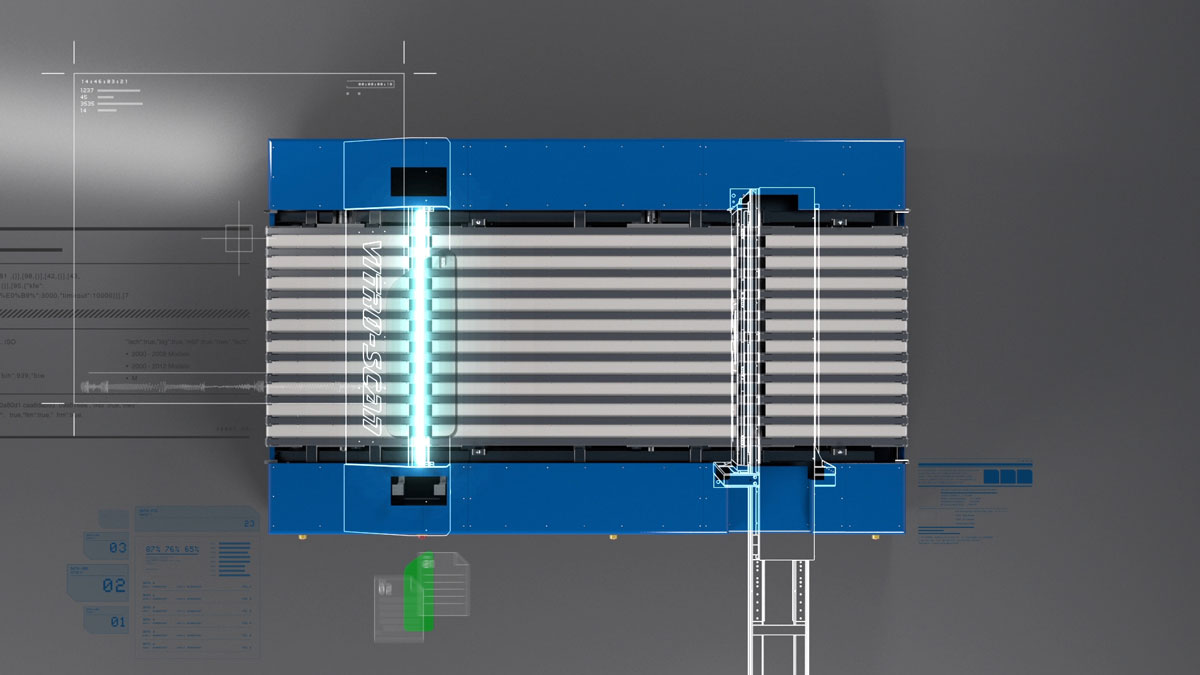

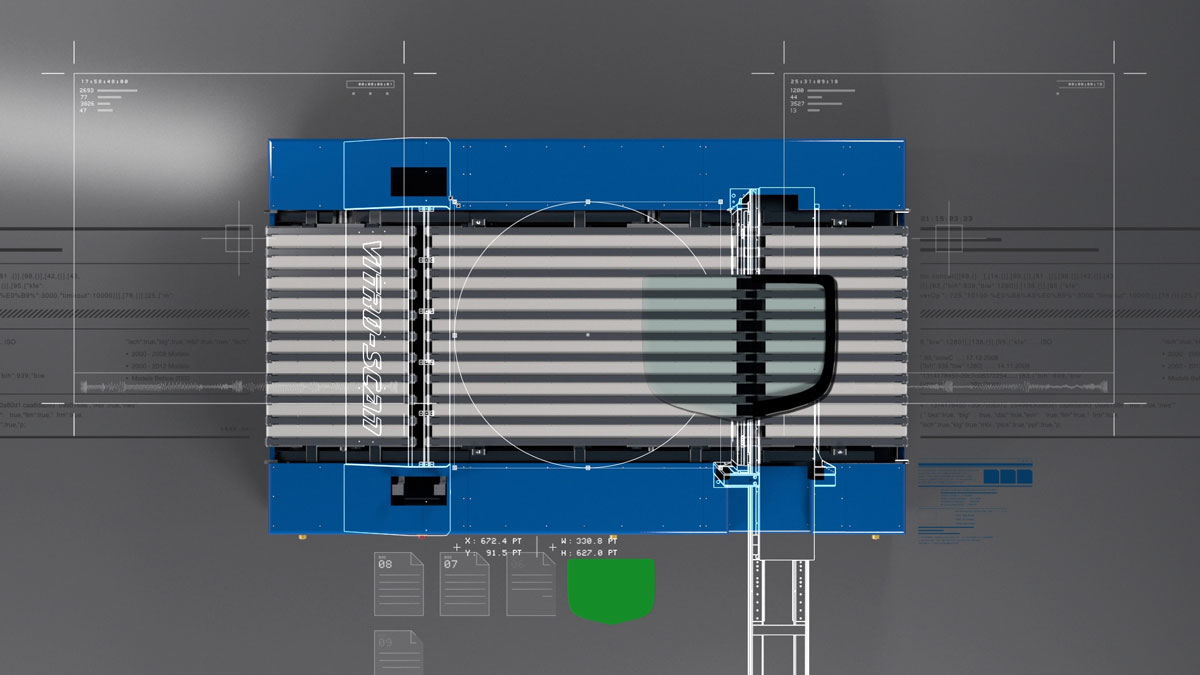

Flawless automation of the non-stop, continuous cycle print process on glass sizes up to 3.300 mm

-

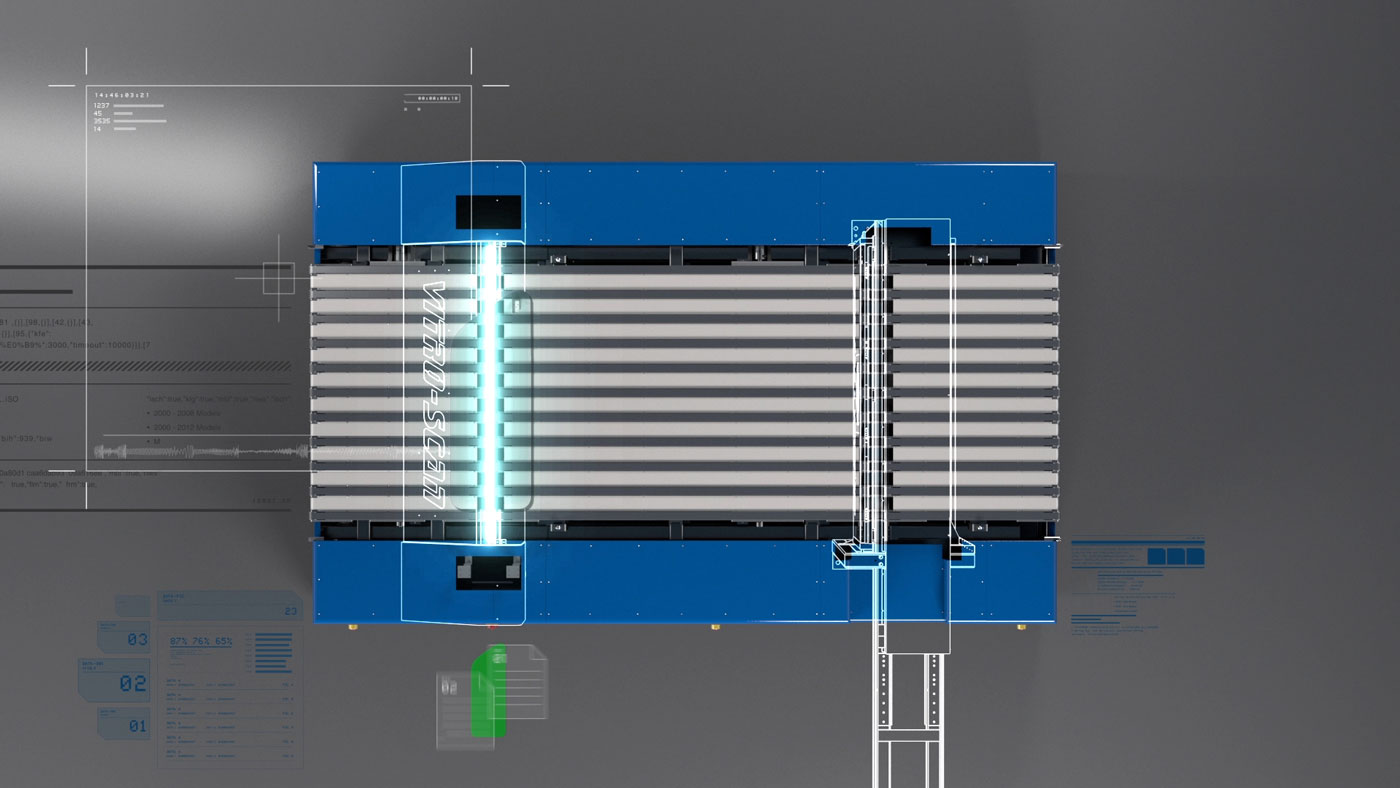

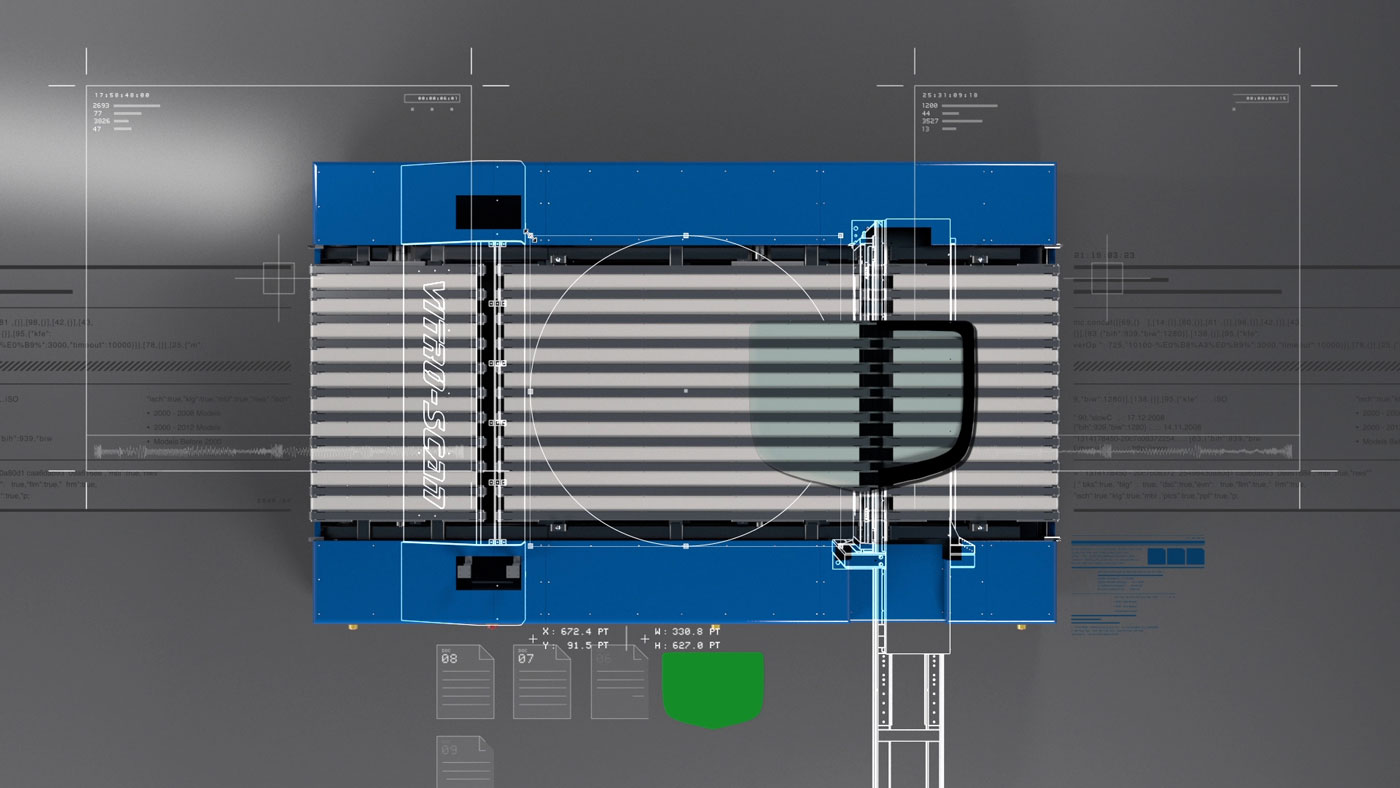

The Vitro Scan tool comes standard to ensure perfect print results, with an operating system capable of automatically re-sizing the file to be printed

-

Extra color channels available